![[CIRCULAR STARTUP TOKYO] Event Report | CIRCULAR STARTUP TOKYO Second Cohort Final Demo & Exhibition Day](https://harch.jp/wp-content/uploads/2025/04/S7R0123-min-825x340.jpg)

[CIRCULAR STARTUP TOKYO] Event Report | CIRCULAR STARTUP TOKYO Second Cohort Final Demo & Exhibition Day

- On Mar 31, 2025

- Accelerator program, CIRCULAR STARTUP TOKYO, Demo Day, entrepreneurship, exhibition, impact business, startup, Sustainable business

Harch Inc. hosted the Final Demo & Exhibition Day for the second phase of “CIRCULAR STARTUP TOKYO,”—a startup support program specializing in the circular economy, conducted in collaboration with the Tokyo Metropolitan Government.

*This article is a republished report from CIRCULAR STARTUP TOKYO titled “[Event Report] CIRCULAR STARTUP TOKYO Second Cohort Final Demo & Exhibition Day”.

Report on the CIRCULAR STARTUP TOKYO Second Cohort Final Demo & Exhibition Day

Circular Startup Tokyo (CST), a startup incubation program focused on the circular economy, was successfully concluded with the Final Demo & Exhibition Day. The program was organized in collaboration between Harch Inc., which operates the circular economy media platform Circular Economy Hub, and the Tokyo Metropolitan Government.

A four-month journey supporting circular economy startups

Over the course of the program, participants gained access to valuable opportunities, including:

- Mentoring from experienced entrepreneurs and experts in the circular economy.

- Lectures on circular business models and sustainable innovation.

- Networking opportunities with domestic and international circular economy organizations, large corporations, financial institutions, investors, local governments, and industry specialists.

On the day of the Final Demo & Exhibition, the event welcomed:

- Around 20 mentors and advisors

- Representatives from about 10 program partner companies

In addition, outside the pitch venue, participants from both the first and second cohorts showcased their projects and products, offering a glimpse into their circular economy-driven innovations.

Pitch session with expert feedback

Fourteen teams took the stage to deliver seven-minute pitches. Each presentation was followed by expert feedback from a distinguished panel of investors and mentors, including:

- Hirokazu Kitahara / Partner, Archetype Ventures

- Masafumi Kawai / Advisor, UTokyo IPC

- Tatsuya Mori / Incubator, Investment Division, Kamakura Investment Management Co., Ltd.

- Shingo Yoshizumi / CEO, Kaman, Inc.

- Sachiyo Kojima / CEO, RINNE Inc.

- Shogo Minemura / CEO, ZOUKEI-KOUSOU

- Yuji Enomoto / Executive Officer & Head of Social Business Division, Shinto Tsushin Co., Ltd.

- Hideki Miyagawa / Manager, Circular Economy Business Development, Veolia Japan / Part-time Lecturer, Nagasaki University Graduate School of Engineering

- Shinsuke Konaka / Senior Manager, Technology-Based Finance Team, Sustainability Promotion Division, Sumitomo Mitsui Trust Bank

- Asako Saito / CEO, BLOOM Co., Ltd.

- Kouzou Eguchi / Fund Manager, Kamakura Investment Management Co., Ltd.

- Shinji Ohata / CEO, O Ltd. / Founder, MAD (Makaira Art & Design)

- Kuniko Sekine / CEO, Koreyako Co., Ltd. & COME FULL CIRCLE

Below are highlights from the pitches and expert feedback.

Startup Pitches

Course A: Scaling Up, Fundraising & IPO Preparation

Takahiro Tsubonuma & Hanae Noda / Shibuya Fertilizer LLC (in Japanese)

Shibuya Fertilizer LLC is advancing urban circular economy initiatives by repurposing commercial food waste, particularly through its flagship food project, Circular Sweets®.

In Shibuya, over 300,000 tons of food waste are generated annually. Some of this waste is turned into fertilizer at a recycling facility in Ibaraki Prefecture and used to cultivate sweet potatoes. S

Shibuya Fertilizer has developed a circular business model that brings the harvested sweet potatoes back to Shibuya, where they are turned into sweets and sold locally.

Their newly introduced Flower Sweet Potato is planned to be sold as a new Tokyo souvenir that symbolizes the connection between urban and rural areas. The company incorporates food waste reduction into its production methods and uses thinned wood for packaging to reduce plastic use. Additionally, they are launching new research initiatives to support plastic-free packaging development. By collaborating with waste reduction efforts at large urban commercial complexes, they have created a business model that reduces sales costs while increasing revenue.

With a target audience of consumers in their 20s and 30s, the company aims to carve out a unique position in Japan’s ¥350 billion souvenir market by emphasizing the narrative of urban-rural connection. Their expansion plans include department stores, commercial facilities, hotels, airports, in-flight meals, and e-commerce.

Looking ahead, they aim to scale this circular model beyond Japan to megacities with populations exceeding 10 million. By the 2030s, they aim to exceed ¥20 billion in revenue from their sweets business. Through food waste reduction, increased agricultural value, and stronger regional cooperation, they aspire to create a global brand from “unwanted” resources and shift the 20th-century mass production and consumption food industry into a circular model fit for the 21st century.

Yuta Ara & Yuji Harada / Ripples Co., Ltd. (in Japanese)

Ripples Co., Ltd. promotes the adoption of horizontally recycled containers in collaboration with factories in Yamagata Prefecture. With a mission to “leverage urban resources to address social challenges,” the company aims to create positive social impact across the fields of environment, welfare, disaster response, and education.

Their horizontally recycled containers can be recycled without washing by simply peeling off the film after use. Once collected, the containers are processed into pellets and remade into new containers. Compared to conventional containers, this solution reduces waste weight by 97%, and for every 100 containers collected, approximately 4.2 kg of CO₂ emissions can be cut.

These containers have already been introduced at universities, the Tokyo Olympics, and theme parks. They are also being utilized in disaster relief and welfare initiatives—for example, as emergency supplies and for job creation by assigning film removal tasks to people with disabilities. The company also offers free containers to children’s cafeterias to ease operational burdens.

Moving forward, Ripples plans to expand its partnerships with restaurant chains, convenience stores, and local governments, with the goal of also introducing their containers at the 2025 Osaka Expo. Additionally, they are initiating support for research and development in plastic-free packaging, offering services to visualize CO₂ reduction, and exploring horizontal recycling for disposable cutlery, all in pursuit of building a truly circular society.

Yudai Tsurusaki & Park Min / Seafood Co., Ltd.

Seafood Co., Ltd. aims to revitalize the fisheries industry by improving fishermen’s working conditions and restoring marine resources. Their seafood matching platform, Seafood, connects fishermen directly with restaurants and retailers, creating a new route to market that complements traditional distribution channels and helps boost fishermen’s earnings.

Japan’s seafood industry faces structural challenges due to its multi-layered distribution system, where high intermediary fees and limited pricing power create inefficiencies. The Seafood platform addresses this by focusing on local fishermen and restaurants, minimizing transportation distance and streamlining trade.

During pilot tests starting in June 2023, the platform successfully helped expand fishermen’s sales channels and reduce procurement costs for restaurants. However, challenges such as high transportation costs for small restaurants, supply consistency, and the adoption of the platform by businesses also emerged.

Moving forward, the company plans to first target high-profile restaurants to build momentum through network effects, then expand to mid-sized and large-scale establishments. That said, they have decided to postpone full-scale commercialization while refining their business model in preparation for a future relaunch.

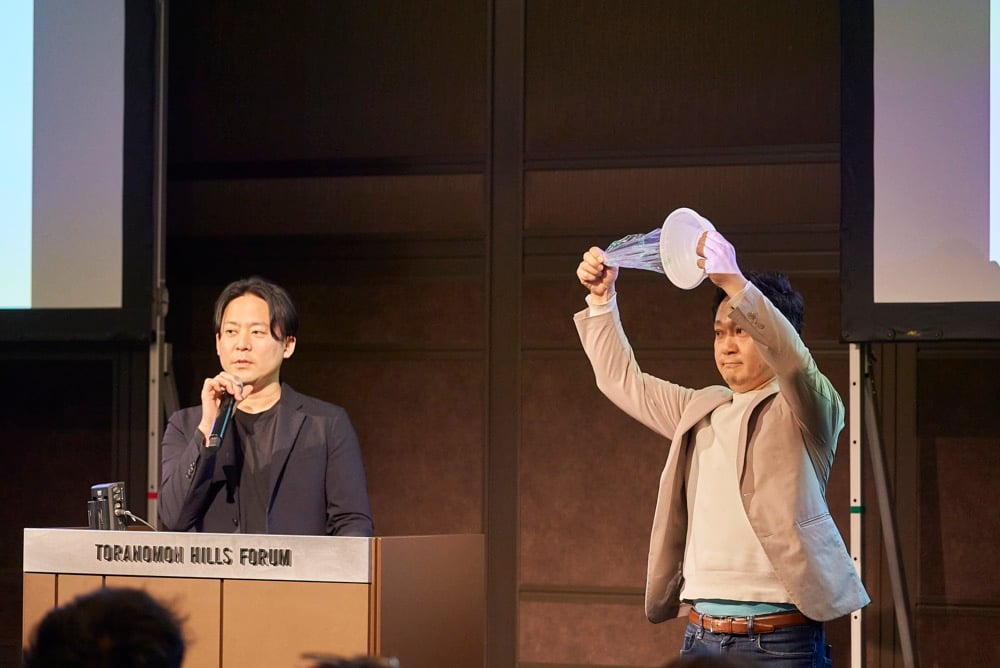

Masashi Shimizu / Microbiofactory Co., Ltd. (in Japanese)

Microbiofactory Co., Ltd. is developing a circular business that repurposes discarded denim to produce recycled indigo dye using proprietary patented technology.

Japan is globally known for its high-quality denim, with many related businesses concentrated in the Okayama and Hiroshima regions. However, the apparel industry as a whole faces significant environmental challenges. Additionally, the European Union has introduced “design regulations” requiring the use of eco-friendly materials—making the shift toward sustainable textiles increasingly unavoidable in Japan as well.

The company collects denim scraps and used jeans, breaks them down using enzymes, and recovers the indigo dye for reuse. They aim to reduce environmental impact through this process. They are currently conducting pilot production in a 4,000-liter tank, providing samples to companies, and testing the dye at textile factories.

Their business model includes selling recycled indigo dye, dyed yarn, and fabrics, as well as producing denim apparel. Very few companies globally specialize in dye recycling, and Microbiofactory’s combination of patented technology, mass-production expertise, and strong industry partnerships give them a unique competitive edge in Japan.

They plan to begin mass production in 2025, expand internationally by 2027, and aim for a business sale or IPO by 2030. They are currently seeking corporate partners and investors to support their continued growth.

Shuta Nakamura / Circloop Inc. (in Japanese)

Circloop Inc. is on a mission to make sustainability the norm by rethinking disposable culture in offices and creating comfortable and sustainable circular spaces. To achieve this, the company has developed a reusable cup-sharing service.

Many offices currently generate a significant amount of waste from disposable bento boxes and paper cups. Circloop proposes an alternative: an office environment that does not rely on single-use items.

Key features of its reusable cup service include:

- Full-service support, covering washing, delivery, and collection.

- Convenience equivalent to disposables, smooth seamless adoption.

- Visualization of environmental contributions, allowing users see their impact.

This service helps achieve zero waste and reduces greenhouse gas emissions. Users have reported positive effects, such as feeling a sense of contribution to sustainability and enhanced team unity within the company.

Circloop’s business model is based on a fee of 14 yen per use, making it cost-competitive with disposables when factoring in reduced waste disposal costs and increased reuse rates. The service has already been used over 540,000 times, and the company aims to reach 3 million cups reused daily by 2030.

Looking ahead, Circloop plans to introduce custom-branded cups to support internal branding initiatives and launch a beverage refilling service as an alternative to single-use plastic bottles and cartons.

Course B: Creating Social Impact & Establishing a Business Foundation

Takeshi Enomoto / University of Shizuoka

Takeshi Enomoto of the University of Shizuoka is developing analytical technology to ensure the safety of recycled plastics.

As society transitions toward a circular economy and demand for recycled materials grows, concerns have arisen over the presence of harmful chemical substances in recycled plastics. Some of these chemicals may pose health risks through skin contact, making chemical traceability increasingly important.

Conventional analysis methods were limited to detecting only regulated substances. Enomoto has developed a technology that enables comprehensive measurement of unknown chemicals and risk prediction. He has also created a Digital Product Passport (DPP) system that allows recycling companies to submit samples and publish analysis data on a digital marketplace. This system uses a transaction-based pricing model, ensuring both cost efficiency and data transparency.

By 2030, demand for recycled plastics in Japan is projected to reach 180,000 tons. This technology is expected to be particularly valuable in industries such as automotive manufacturing, where safe recycled materials are essential.

Enomoto is currently conducting a pilot project that uses his technology to upcycle discarded fishing gear from Ishigaki Island into 100% recycled sunglasses. He is actively seeking corporate partners to support and expand this initiative.

Akiha Matsue

Akiha Matsue has proposed a business model that combines diaper carbonization technology with workforce support services for healthcare and elder care facilities. This approach reduces diaper disposal costs, enabling facilities to reallocate resources toward nurse mental health programs and career development opportunities.

The carbonization system compresses 240 kg of diaper waste into just 4 kg per day, significantly easing the waste management burden on hospitals and nursing homes. Each unit costs approximately 4 million yen and can reduce industrial waste disposal costs by up to 90%.

Matsue is also developing a career support platform for nurses, offering mental health care services and listening sessions. As the healthcare market grows, she plans to expand both individual and enterprise-facing services.

Looking ahead, she aims to introduce this solution to hospitals, nursing homes, daycare centers, and local governments, while also exploring applications in disaster preparedness. By integrating waste management with workforce development, she envisions a sustainable model that benefits both people and the environment.

Masachika Nagasue / GMG Corporation

GMG Corporation has developed “MoRack.” — an algae-based cultivation system designed to support a more sustainable future.

Algae are known for their ability to absorb CO₂ through photosynthesis, offering a promising solution to environmental challenges. “MoRack.” leverages this capability by transforming bus stops into functional algae cultivation units.

This system is designed to:

- Capture CO₂, contributing to carbon neutrality

- Generate electricity, supporting renewable energy adoption

- Serve as local information hubs, enhancing community and urban infrastructure

In addition to its environmental benefits, the system generates revenue through advertising and carbon credit sales, making it financially sustainable. GMG expects the project to reach profitability within five years, thanks to its low initial investment and minimal maintenance requirements.

The company has outlined a three-phase growth strategy:

- Phase 1: Roll out “MoRack. Bus Stops” across Japan

- Phase 2: Extract algae oil for use in food and cosmetic products

- Phase 3: Expand applications to agriculture and renewable energy sectors

GMG is currently seeking funding, installation partners for bus stops, and advertisers to support the initiative.

Hiroko Sudo / Bluebird

Bluebird is developing an inclusive housekeeping matching service that connects clients with individuals who have a stutter.

Approximately 40% of people with a stutter also experience social anxiety disorder, making traditional employment challenging. Bluebird’s service offers 30-minute housekeeping sessions, providing a supportive and understanding work environment for people with a stutter.

Targeting the 98% of people who have never used housekeeping services before, the platform offers an affordable 30-minute session for 2,000 yen. Services include cleaning, cooking, and other customizable tasks based on the provider’s unique strengths.

To promote mutual understanding and reduce mismatches, providers upload short introduction videos explaining their communication preferences and any specific support they may need.

Currently, Bluebird is conducting a supervised pilot trial under the guidance of experts. In the future, the company plans to expand the platform beyond stuttering to support individuals facing various employment barriers, with the ultimate goal of creating a more inclusive society.

Miyu Yagami / Gaiapost Inc. (in Japanese)

Gaiapost Inc. is developing biodegradable diapers designed to eliminate waste and improve soil health, with the goal of building a circular economy where child-rearing and environmental sustainability go hand in hand.

Japan generates approximately 2.3 million tons of disposable diaper waste annually, placing a growing burden on incineration facilities and the environment. Diapers tend to be heavy from moisture absorption, emit unpleasant odors, and are difficult to recycle due to their composite materials. Daycare centers face particularly high disposal costs, and municipalities are grappling with aging or consolidated incineration infrastructure.

To address this, Gaiapost is developing a biodegradable pad to be used with reusable cloth diaper covers. Utilizing technology developed at Osaka University, the company aims to achieve high absorbency while ensuring the pads can be composted. Their primary target markets include eco-conscious families, daycare centers, and municipalities struggling with waste management.

With support from CST, the company has created prototypes and is continuing to refine the design. A pilot program is planned for 2025, with commercialization expected in 2026. Looking ahead, Gaiapost intends to expand into related markets such as adult incontinence products, feminine hygiene products, and pet pads.

Wang Zhenjiang / Toshiba Corporation

Zhenjiang Wang from Toshiba Corporation is developing an AI-powered system to reduce bulky waste and promote reuse.

Japan generates around 570,000 tons of bulky waste each year, of which approximately 15%—around 18 million items—are still reusable. However, due to high collection costs, most of these items end up being discarded.

This new system allows residents to photograph unwanted items, after which AI determines whether they are reusable. If deemed reusable, the item’s information is shared with collection agencies to help reduce costs and increase reuse rates.

Wang is also working with local governments to integrate the system into municipal websites, making it easier for residents to request collection services. This enables free pickup, benefiting residents, municipalities, and reuse businesses alike.

With an estimated market size of ¥5.6 billion, the initiative aims to achieve profitability by 2028 and reach annual sales of ¥4.7 billion by 2032. Wang also plans to expand into home appliance recycling and material recovery, further advancing the circular economy.

Atsushi Morita & Yuriko Wada / Paper Parade Inc. (in Japanese)

Paper Parade Inc. is a design firm that harnesses the power of design to drive urban circularity. The company is particularly focused on tackling the issue of outdoor advertisements, where large volumes of durable materials are discarded after only short display periods.

The core challenge lies in intellectual property rights—such as copyright, portrait rights, and trademarks. To address this, Paper Parade has developed a proprietary technique called “Secret Processing,” which enables the reuse of materials while safeguarding advertisement designs. The company also offers a one-stop system that handles everything from collection to design planning, processing, and delivery. This initiative has been selected for I-OPEN, a project by the Japan Patent Office aimed at solving social issues through the use of intellectual property.

One of Paper Parade’s flagship projects, Ligaretta, transforms advertising banners into fashion items—achieving both waste reduction and new revenue streams. The company also runs various upcycling projects, such as converting debris from redevelopment sites into ink and repurposing surplus flyers into planters.

Paper Parade is currently seeking brand collaborators. Its goal is to build a circular system that is not only visually appealing, but also conceptually and philosophically “cool.”

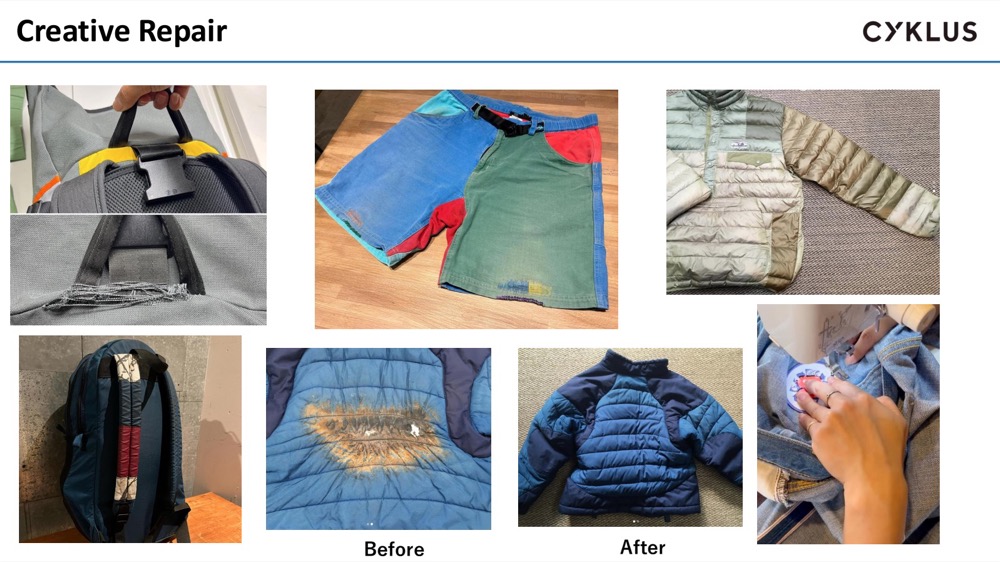

Takeo Hirata / Cyclas LLC (in Japanese)

Takeo Hirata of Cyclas LLC is leading the “Co-Creation Repair Center Initiative,” a project aimed at shifting the apparel industry toward circularity.

In today’s society of mass production and consumption, Japan discards approximately 500,000 tons of clothing annually. Around 70% of lifecycle CO2 emissions occur during the production phase. Extending the lifespan of garments through repair and reuse is one of the most effective solutions—for example, increasing a garment’s use from five to eight years can reduce CO2 emissions by up to 28.8%.

While countries like France offer repair subsidies and Amsterdam has established joint repair centers between brands and municipalities, Japan already has cultural foundations for repair, rooted in values like mottainai and kintsugi.

To take advantage of this cultural readiness, Hirata proposes creating collaborative repair centers where brands, repair technicians, and sewing factories can jointly offer official repair services. This allows customers to access trusted repair options while providing brands with opportunities to reduce costs and increase customer loyalty.

Looking ahead, Cyclas aims not only to promote repair but also to build a holistic circular economy ecosystem. This includes collaborating with skilled repair professionals, partnering with social welfare organizations, and creating educational opportunities. By redefining repair as a “cool and conscious action,” the company seeks to foster a more circular society.

Chol Gyu Lee

Chol Gyu Lee is developing innovative circular products made from urban food waste.

Food waste makes up roughly 30% of Japan’s total waste. Most of it is incinerated, costing around ¥245 billion annually in disposal fees and contributing significantly to CO₂ emissions. Despite efforts to promote composting, its use in urban areas remains limited, often resulting in surplus even when distributed for free.

To tackle this issue, Lee has developed pellets made by combining food compost with biodegradable plastic. The prototype consists of 80% compost and 20% biodegradable polyethylene, effectively resolving odor concerns.

Currently, Lee is focusing on educational applications and has developed a morning glory growing kit for elementary and junior high schools using this material. This initiative aims to reduce reliance on single-use plastics in classroom tools. He is also working to improve the material for broader applications, with the goal of building a sustainable and scalable circular system.

Special Award Ceremony

Following the participant pitches, the Special Award winners were announced.

- The “Kamakura Investment Award” was presented to Tsurusaki of Seafood Co., Ltd.

- The “Sumitomo Mitsui Trust Bank Award” was awarded to Sudo of Bluebird

Regarding the Kamakura Investment Award, Eguchi commented:

“I’ve attended countless programs like this, but this is the first time I’ve seen someone decide to withdraw from their business at the final presentation stage. It was a shocking decision. However, as the saying goes, ‘If you give up, that’s the end of the game.’ I believe it’s too soon to quit. I hope this funding will support another attempt in the fisheries sector, which still faces numerous challenges.”

As for the Sumitomo Mitsui Trust Bank Award, Konaka shared:

“All of today’s final pitches were truly excellent. However, my evaluation focused on the transformation from the kickoff to today. From Sudo’s presentation, I sensed a journey filled with trial and error that led to this point. That said, today is not the finish line—it’s the starting point. I hope to see the business continue to grow, balancing both social impact and the principles of the circular economy. With that in mind, I present this award as a gesture of support.”

Final Review

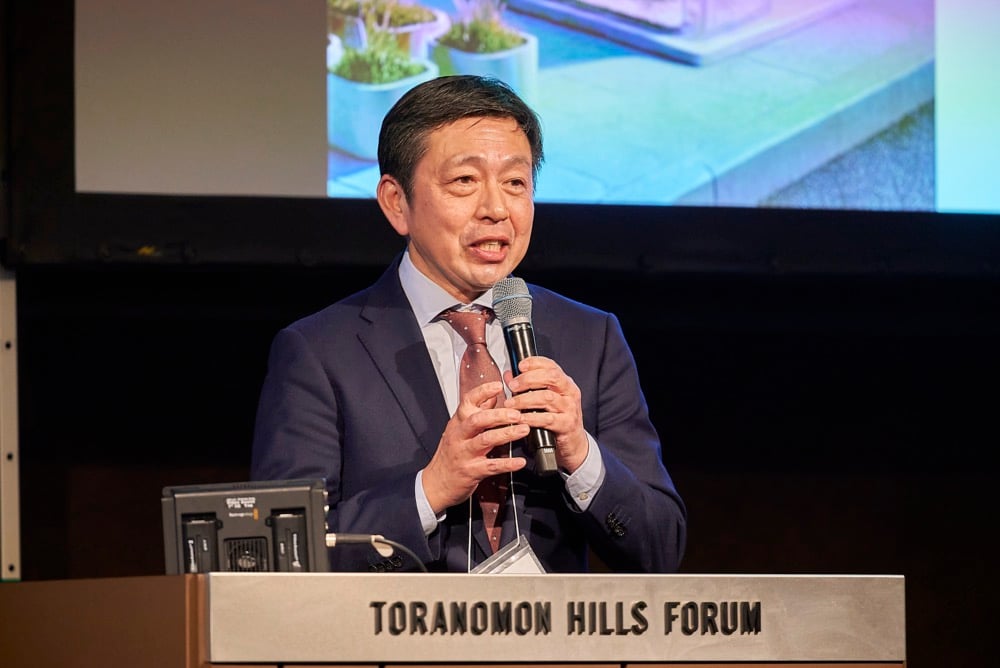

At the conclusion of the event, Hirokazu Kitahara of Archetype Ventures, who played a central role in planning the program, and Yu Kato, the representative of Harch Inc., which managed the program, shared their final remarks.

Hirokazu Kitahara’s Comments

“Since the first cohort, I’ve been involved in this circular economy acceleration program since its first cohort, and it’s been an honor to share this journey with such exceptional entrepreneurs and stakeholders.”

“Today’s presentations once again highlighted the importance of validating business ideas while progressing. Some teams made the tough decision to withdraw from their ventures along the way, but I see this as a sign of the evolution of the acceleration process. It’s far more valuable to identify the right direction early on, rather than continue aimlessly and be forced to exit later. In the U.S., it is common to withdraw immediately when something doesn’t work. In Japan, however, there tends to be an excessive attachment to continuing a venture at all costs, often driven by pressure from VCs. Forcing entrepreneurs—a rare and valuable resource—to stay in a business with low viability is a loss for society. Recognizing a mistake and shifting to a better opportunity is essential for the ecosystem to thrive.”

“Additionally, startups in the sustainability sector are experiencing increasing polarization in terms of fundraising. Successful companies integrate a winning strategy from the start and execute it steadily. It is not enough to simply solve a problem; sustainable growth requires meticulous planning for business expansion, packaging, and designing value propositions tailored to target customers. Relying on passion alone makes it difficult to sustain a business—both financially and emotionally.”

“I also want to emphasize the importance of technology utilization. Many entrepreneurs attempt to solve problems purely by designing ‘systems,’ yet numerous untapped technologies exist in universities and research institutions. On the other hand, researchers often lack the means to implement their technologies in society. Bridging these two groups can create immense business value and enhance global competitiveness. Moving forward, focusing on scalability and achieving overwhelming market competitiveness—rather than just problem-solving—will be key to success.”

“These comments may sound tough, but they come from a place of strong belief in the potential of the circular economy sector. If I believed this field was not suited for startups, I would not push for such high standards. However, I am convinced there is real opportunity here, and I urge participants to aim for even greater levels of business development.”

“Although the second cohort of CIRCULAR STARTUP TOKYO has come to an end, I look forward to seeing evolved versions of this program emerge in the future. I also look forward to reconnecting with you all in new capacities.”

Hirokazu Kitahara

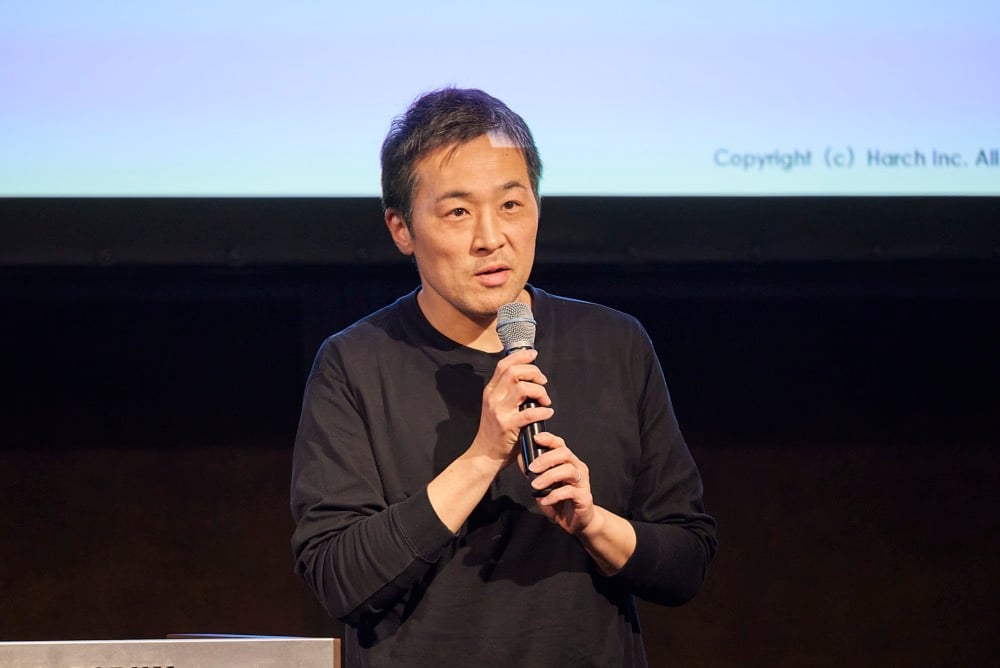

Yu Kato’s Comments

“We launched this circular economy acceleration program out of a strong belief in the future potential of this field. But we also understood that realizing this future requires collective effort—it can’t be achieved by one company alone. While we’re not startup support specialists, we asked ourselves what we could do as a media company, and that led us to launch this program. I’m sincerely grateful for all the connections we’ve made and the opportunity to co-create this platform with you.”

“While “circular economy” might sound niche at first, at its core it’s about shifting from a linear to a circular system—something that spans all industries. I believe everyone who’s part of the economy or society has a role to play in this transformation. Today, we saw business ideas from participants across a wide range of industries and backgrounds. Each one reminded me just how important every effort is in moving this systemic shift forward.”

“This field is still in its early stages, and we’re all learning and experimenting along the way. By sharing, stumbling, and learning together, I hope that when we look back five or ten years from now, we’ll see that the network formed here was the spark for something much greater. I am truly excited to see the participants of this program thrive in the future and create an even greater impact.”

“Though today marks the end of this program, it’s really just the beginning. I hope we’ll stay connected and continue growing together. We’re also preparing to launch new initiatives next year in an even more impactful format, and I’d be thrilled if you stayed involved with us on this journey.”

Yu Kato

Summary

Over the past four months, the second cohort tackled challenges with passion and creativity—refining their ideas into viable businesses through continuous trial and error. At the final presentations, they shared the results of their efforts, receiving high praise from mentors for their growth and progress.

Across two cohorts of incubation, one key insight has become clear: each initiative contributes to the circular economy not only through economic viability and sustainability, but by functioning as part of a broader system. To drive systemic change, businesses must position themselves strategically within the ecosystem, collaborate across sectors, and play their roles effectively.

At the heart of this co-creation process is community. Harch Inc., the organizer of CIRCULAR STARTUP TOKYO, will continue to foster spaces for connection and shared learning through incubation programs and media initiatives—ultimately helping to shape a more sustainable society.

Exhibit by PHI Corporation, a participant in the first cohort

Exhibit by HELSINKINOKO, a participant in the first cohort

Products from B Corp-certified companies on display

Group photo of participants, mentors, and partner companies

[Related Page] [Event Report] “CIRCULAR STARTUP TOKYO Second Cohort Final Demo & Exhibition Day” | CIRCULAR STARTUP TOKYO

[Related Site] CIRCULAR STARTUP TOKYO